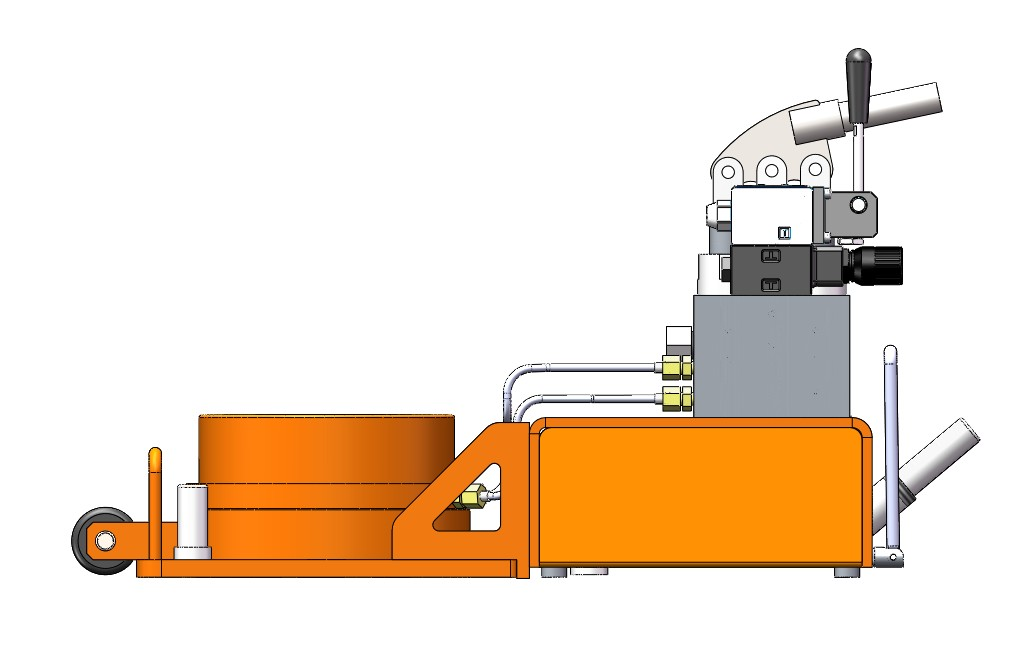

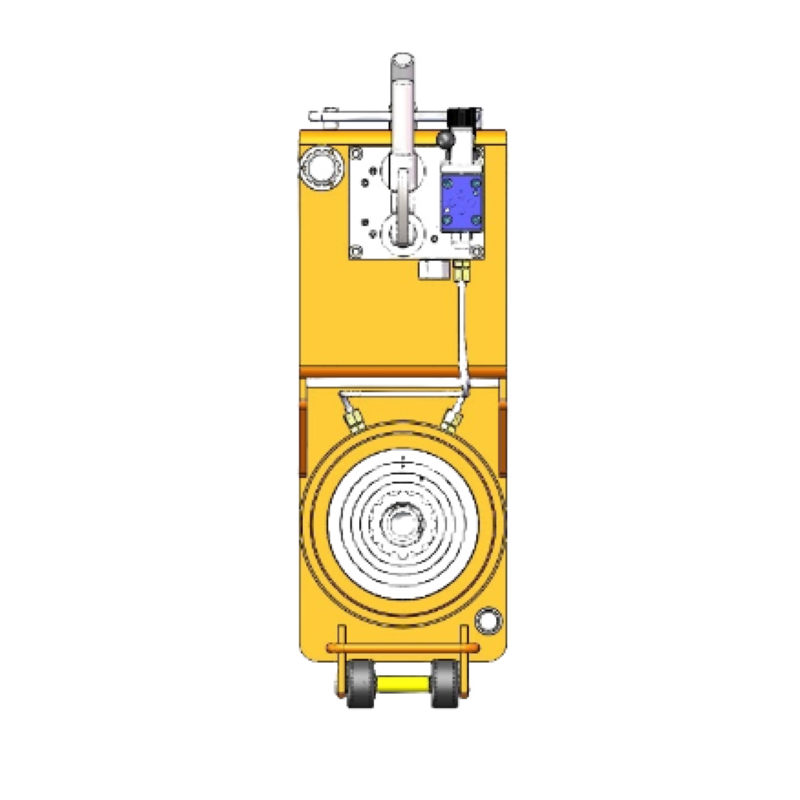

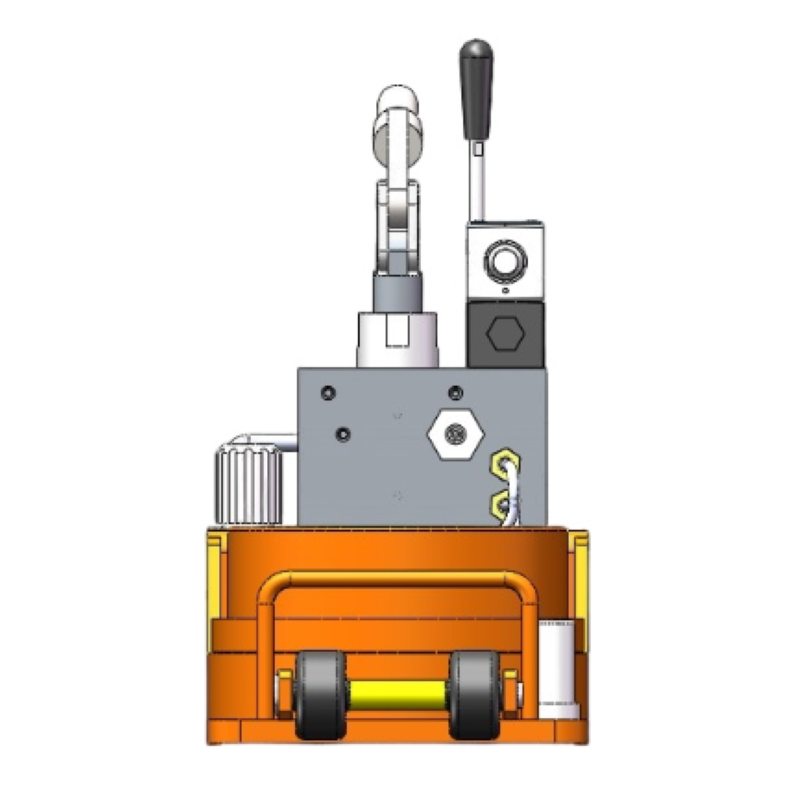

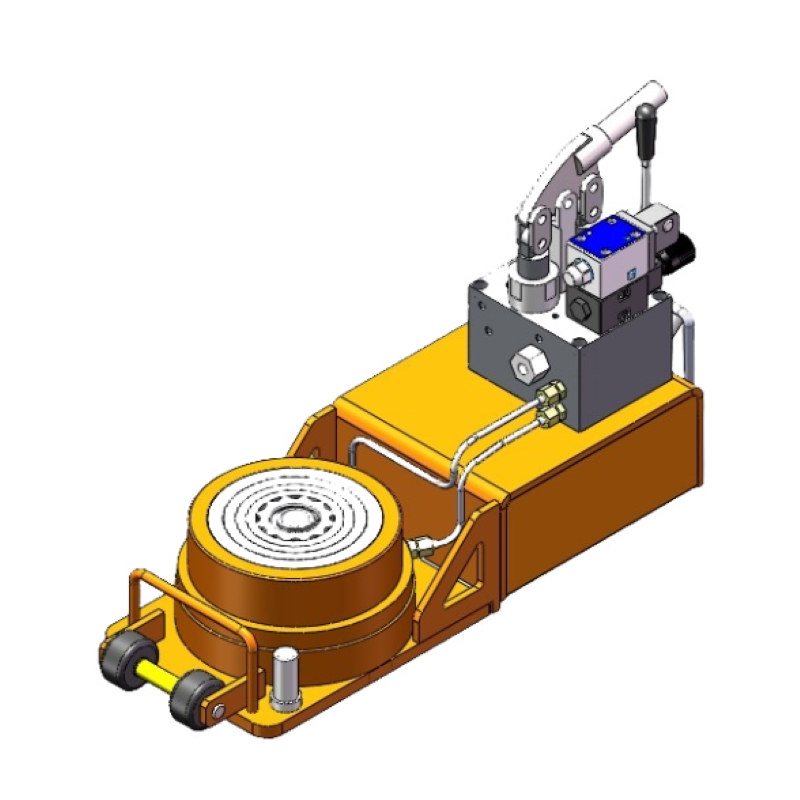

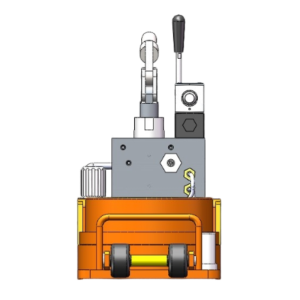

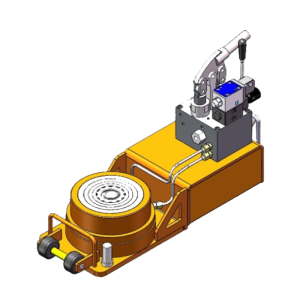

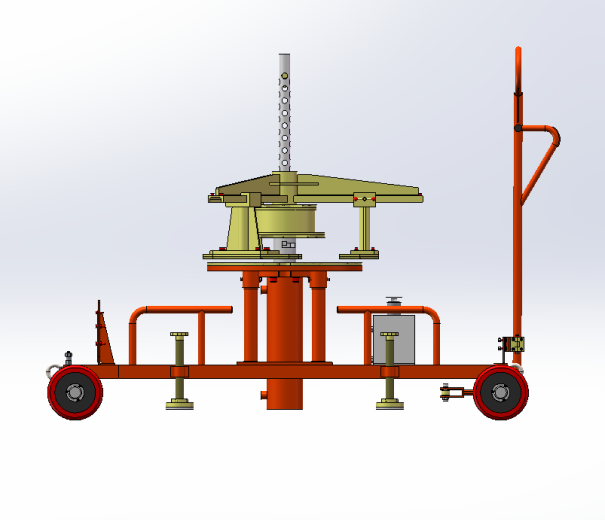

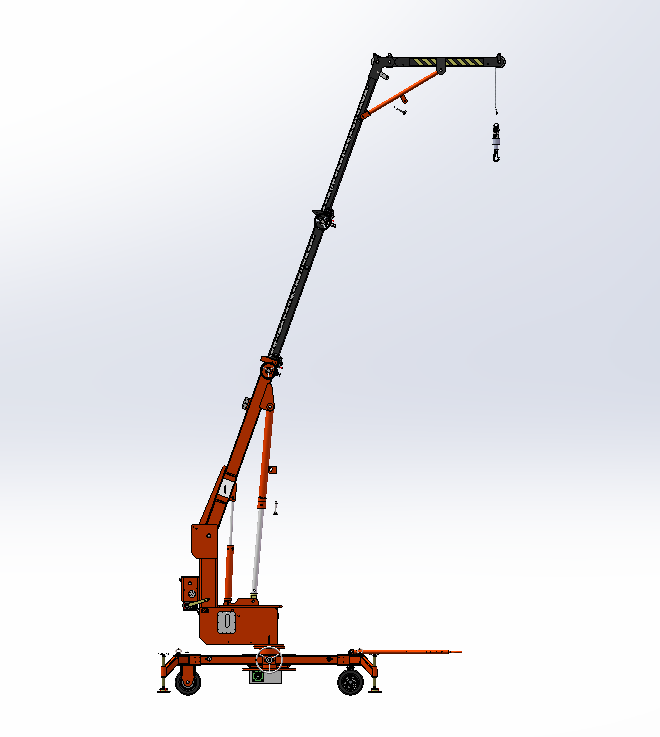

Wheel Jack

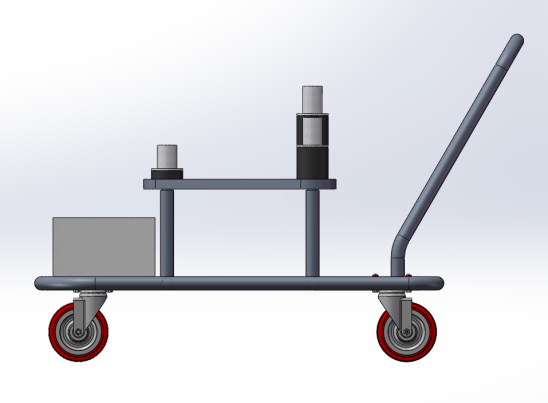

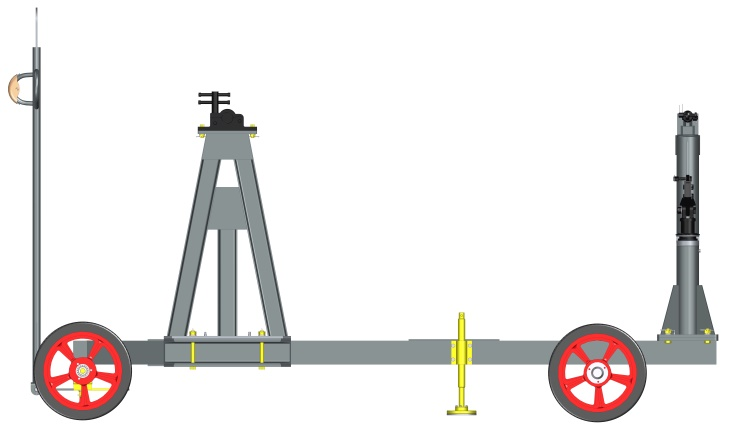

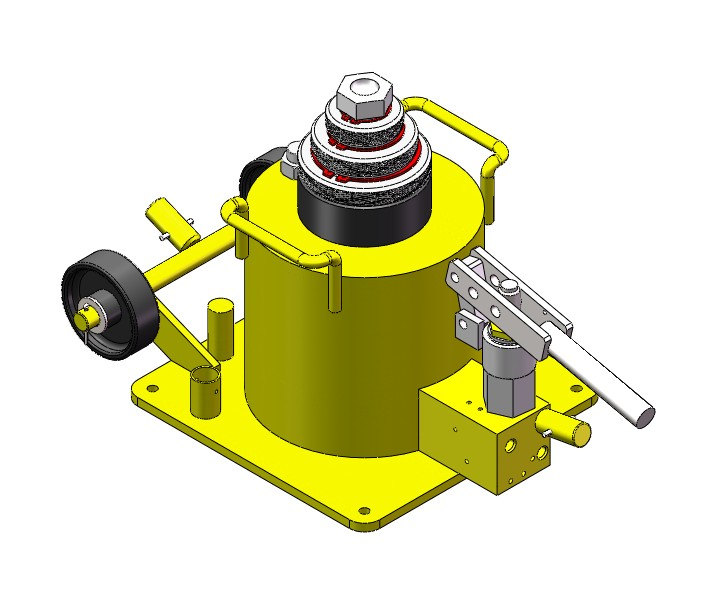

The wheel hydraulic jack is a hydraulic lifting equipment designed for aircraft maintenance. It is mainly used to support aircraft wheels or landing gear for wheel replacement, horizontal calibration, target calibration and other operations.

- Fast And Safe Logistics

- 30-Day Return & Fast Free Shipping