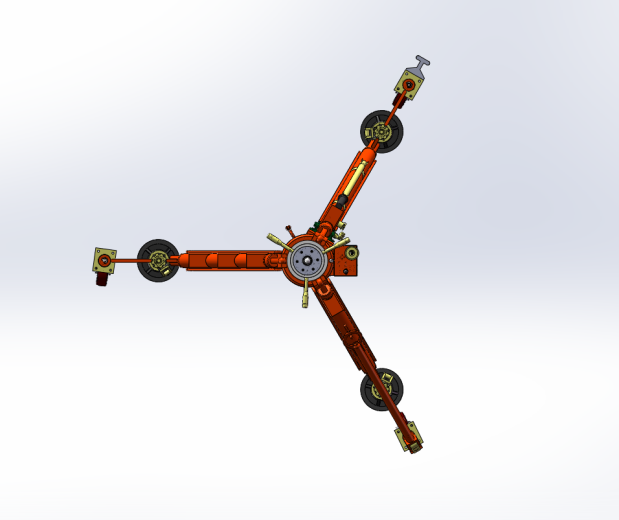

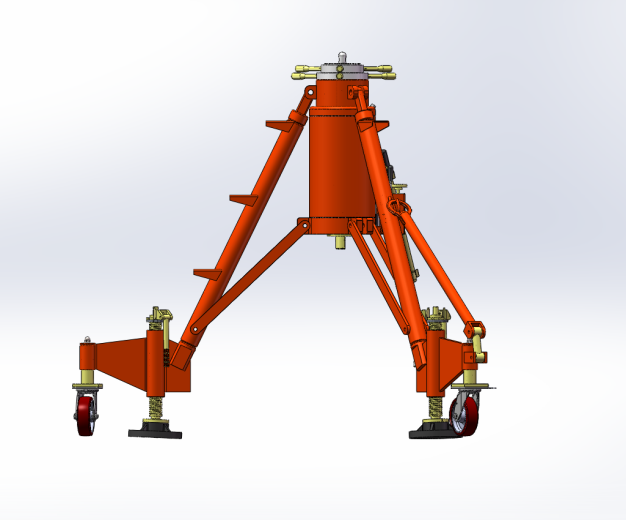

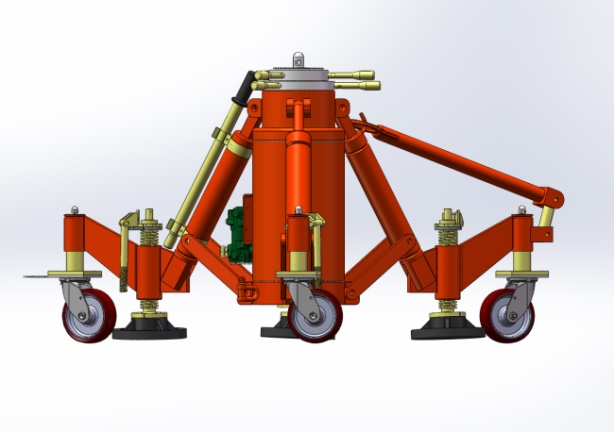

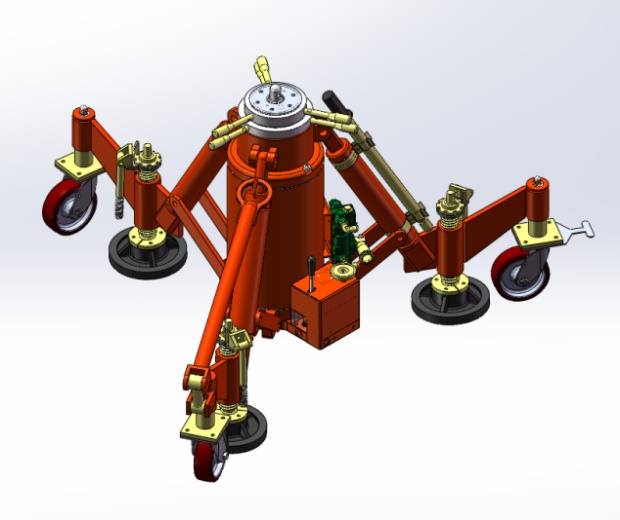

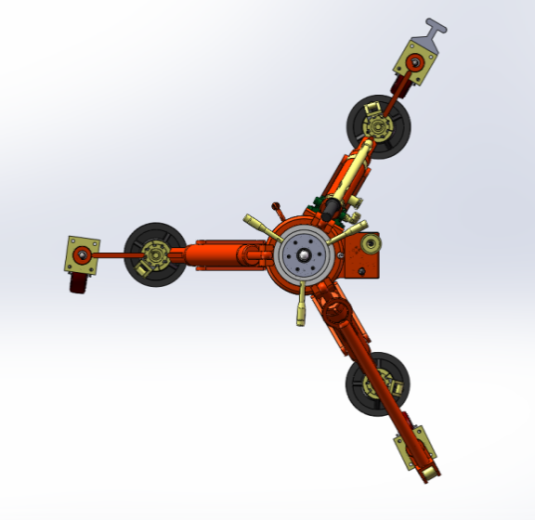

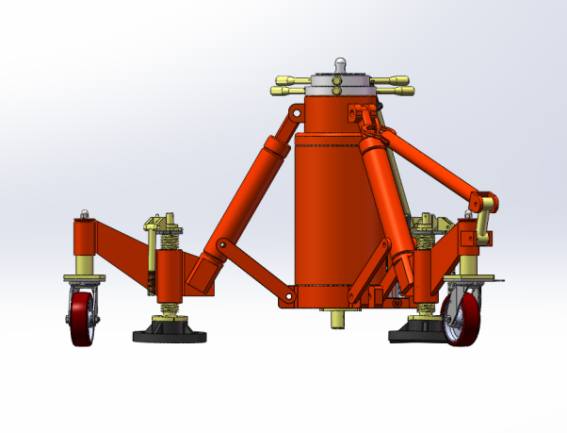

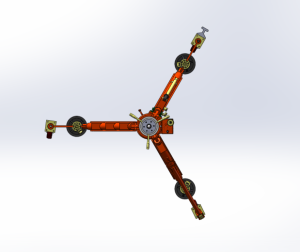

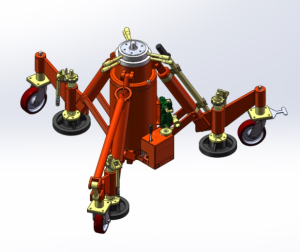

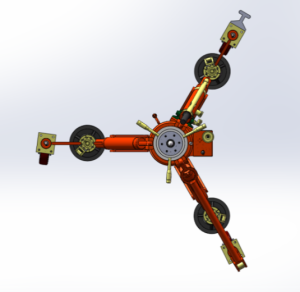

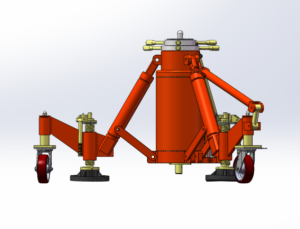

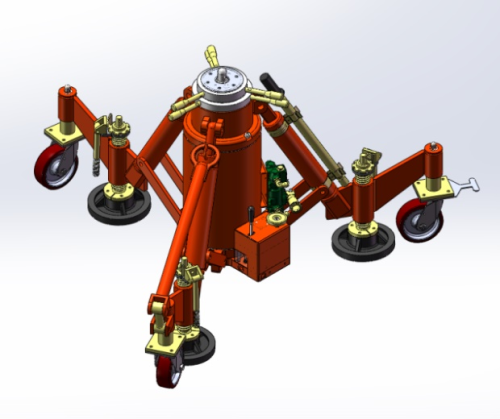

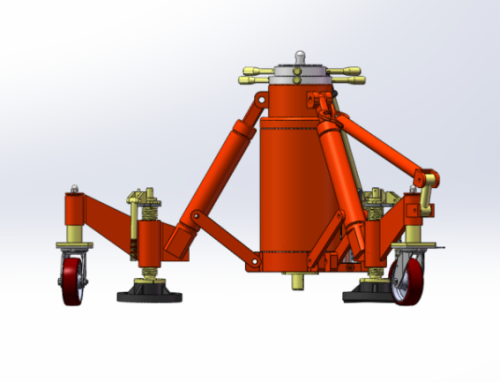

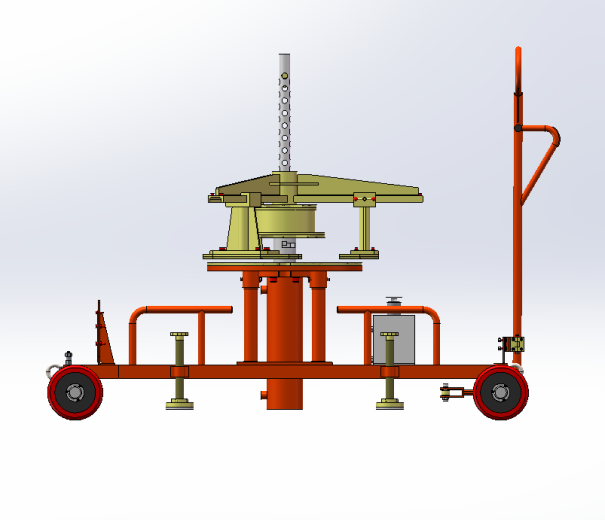

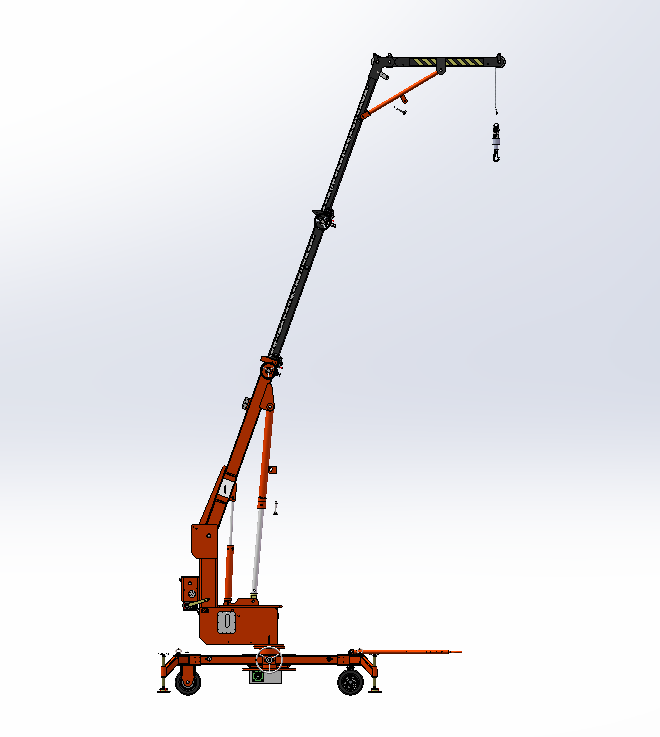

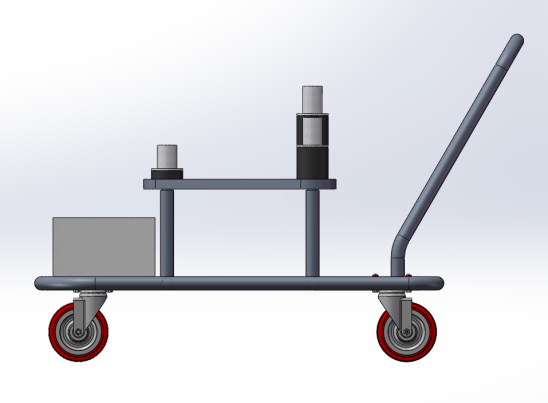

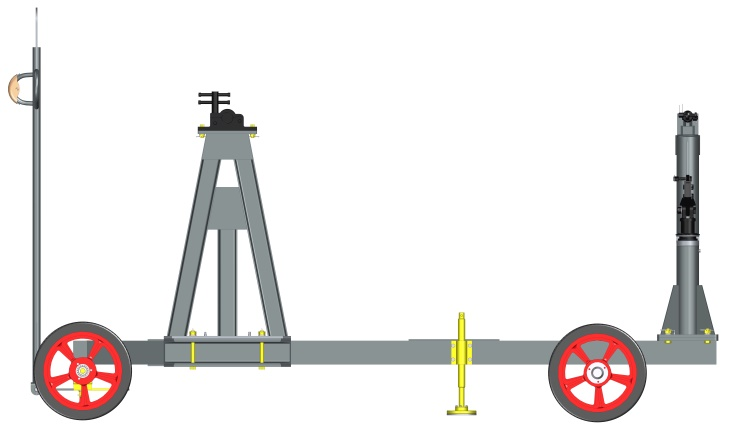

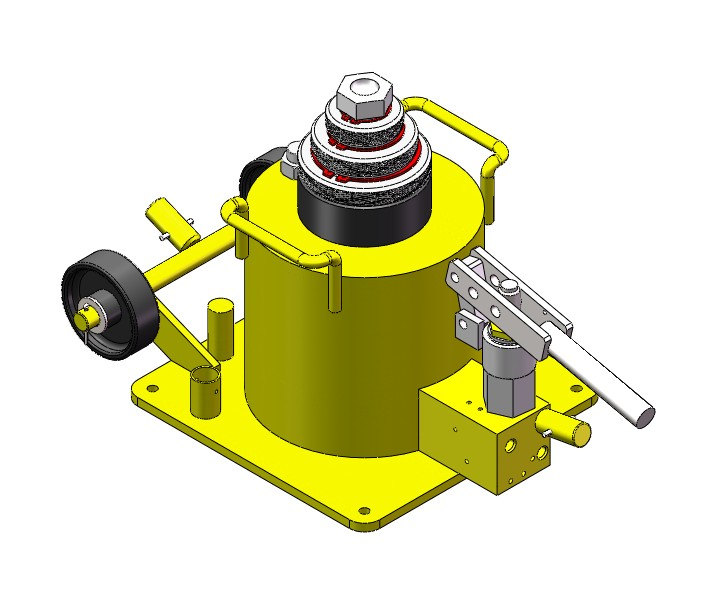

Hydraulic Jack Of A Certain Model

A certain type of hydraulic jack is suitable for supporting and lifting aircraft when the aircraft is conducting leveling, landing gear retraction and extension tests, replacing wheels, and calibration.

- Fast And Safe Logistics

- 30-Day Return & Fast Free Shipping